Cargo-Planner.com Helps Deliver More Life-Changing Mobility Aids to People in Need

Amy Korngiebel

Guest Article

This is a guest article written by Amy Korngiebel at CLASP

According to the World Health Organization, an estimated 70 million people worldwide need a wheelchair for basic mobility and as many as 95% of them do not have one, limiting their social inclusion and participation. The need is greatest in low- and middle-income countries.

Consolidating Logistics for Assistive Technology Supply and Provision (CLASP) is a global distributor of quality, affordable wheelchairs and other mobility aids with a mission to increase access to assistive products where they are needed most.

CLASP provides a solution to many of the supply-side challenges faced by wheelchair service providers in less-resourced settings, such as limited product variety, extensive lead time, and logistical burdens.

We recently partnered with Cargo-Planner.com to increase the efficiency of our operations so more children and adults around the world can access the products they need for health and well-being.

Loadbuilding Case

A customer in Kenya placed an order with CLASP and opted to maximize their full container load (as many customers do) when ordering from our Shanghai warehouse. Our general operations rule is to hold the customer to a limit of 80% container capacity so there will be no loading difficulties for the warehouse team.

The Kenya order consisted of 48 SKUs in 362 cartons, totaling 61.437 cubic meters (CBM) which is over our 80% load limit. As a result, our warehouse team rejected the load and advised the customer to reduce their order to 58.0 CBM.

To make matters worse, the order was pre-paid. Asking the customer to change their order just before shipping could strain a valued relationship.

Reducing the load would mean fewer products for people in need. Our team knew there must be a better way to ensure the maximum number of products per shipment.

Cargo-Planner.com to the Rescue

Our operation and sales teams determined that a detailed container load plan may be the best solution to satisfy all parties concerned: our customer, our warehouse, and our operations and sales teams.

At the time, we were not using any load planning software and had no direct experience working with any of the many software solutions in the logistics market. After some research, we found several options that seemed suitable, but were quickly eliminated because they were:

- Too expensive

- Not optimized for ocean containers and airfreight pallets

- Not sharable across a global organization

- Could not upload packing lists

- Could not accommodate part numbers

- Results were not sufficiently detailed for step-by-step loading

After further research, one product stood out as the best option for our needs: Cargo-Planner.com

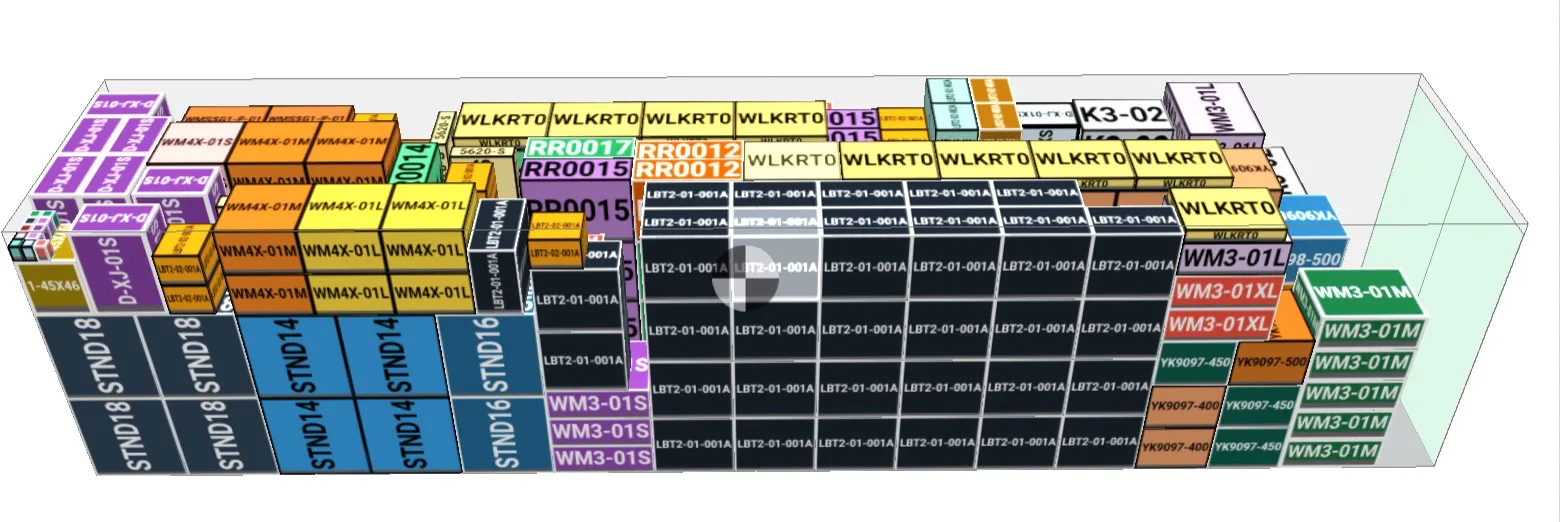

Our sales team was able to quickly load the packing list details online and output a container load summary with detailed step-by-step loading instructions, including color coded cartons displaying our part numbers. The load plan was also available in excel format.

We sent the detailed load plan to our Shanghai warehouse and they had no trouble fitting the full order into the container.

We are very happy with the Cargo-Planner.com software and intend to use it for all full container loads and all palletized airfreight shipments. Thanks to Cargo-Planner.com, even more people with disabilities around the world will receive the product they need to live their best lives.

More About CLASP

CLASP is a USAID-funded project implemented by Momentum Wheels for Humanity. CLASP stocks and is ready to ship a range of high-quality, affordable mobility aids selected by an independent panel of clinical and technical experts. CLASP promotes appropriate service provision through a global network of service providers who are leaders in delivering quality provision in their communities. Through CLASP, governments and other large-scale buyers can deliver a variety of products to meet their population’s unique needs faster and more efficiently.

Learn more at clasphub.org.