Cargo-Planner Docs

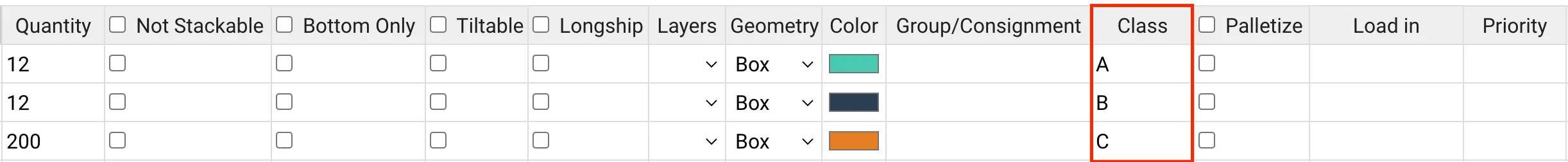

Load settings

Sometimes sssyou might want to adjust the default load settings in order to better suit your requirements. The Load settings view can be accessed from the Setup view.

General settings

Performance & Limits

Max calculation time

A number (defaults to 2), between 0 and 15 that sets the timeout for the load engine (in seconds). In general if you have multiple container types and many different cargo types a better result can be generated by increasing this number.

Optimization level

Better organization

This option will try to load cargoes of the same kind close to each other. Organization is priortized above utilization which will lead to simpler containers with lower efficiency.

Normal

This is the balanced option between organization and utilization. Used as default.

High utilization

This option priorizes utilization and will often achieve higher efficiency with the drawback of getting a less organized load plan.

Max number of containers

Specify a maximum number of containers that can be used when calculating. Leave this field blank if you do not want any restrictions.

Loading style

Second objective

Second objective can be set to minimize used length or minimize use height. See description of options below.

Minimize used length

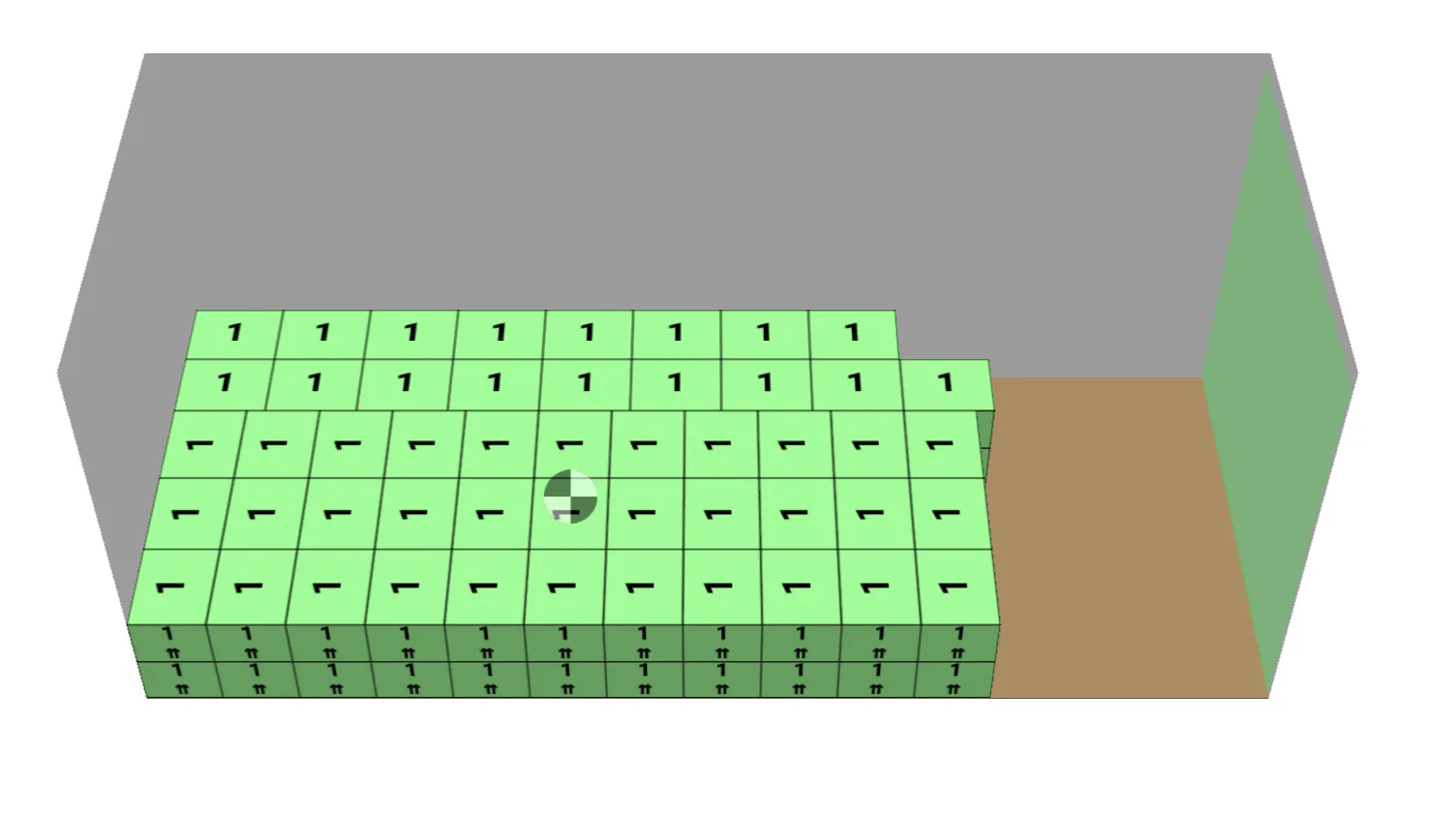

Will try to minimize the loading meters and “push the cargoes against the back”. This is the default when creating truck load plans.

Minimize used height

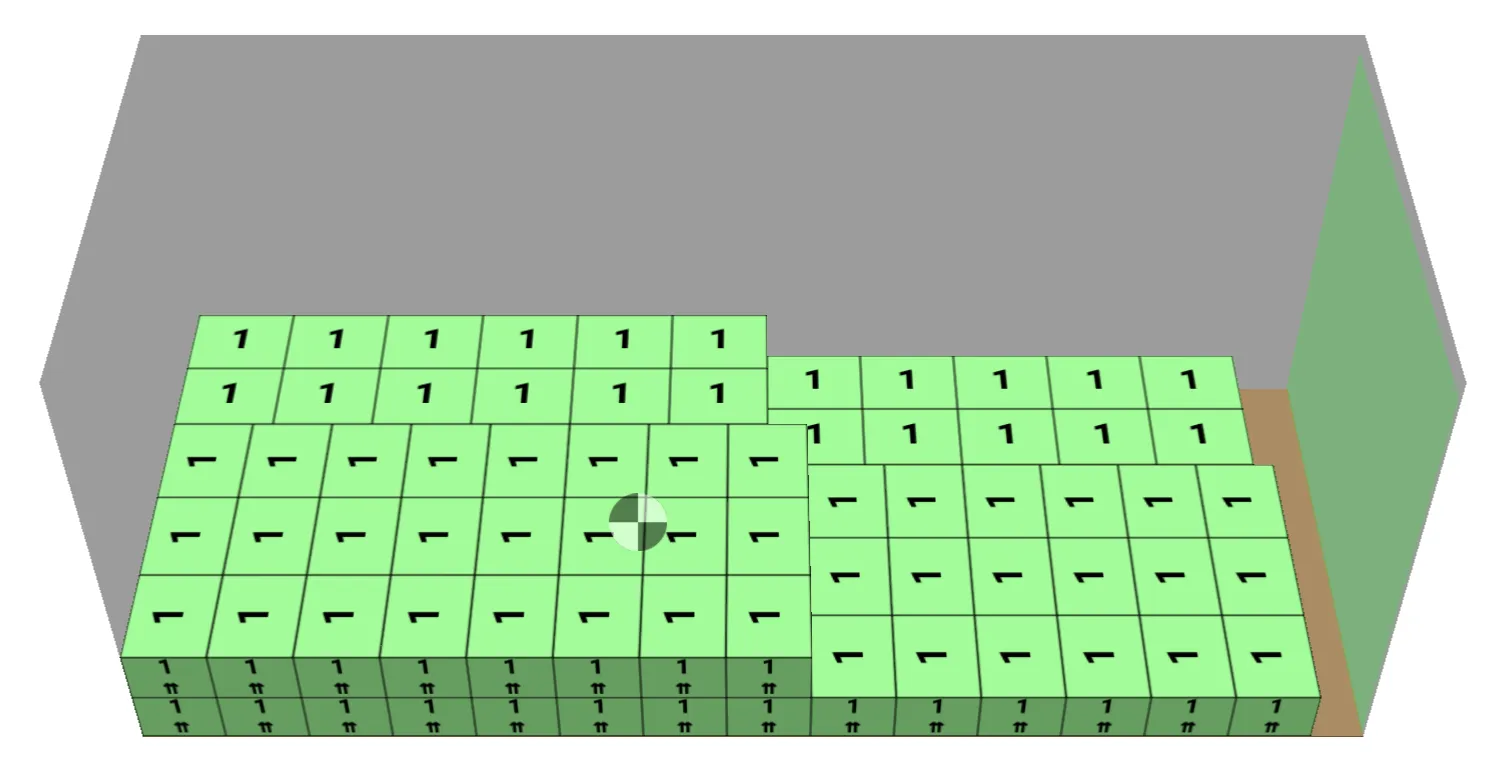

Will try to minimize the used height inside the container.

Load from bottom up

Will load the cargoes from floor and upwards. As an example - when loading a sea container you do sometimes want to load stacks of boxes - outwards towards the door. For pallets though you usually build layer by layer which is why this setting is set to true for air containers & pallets

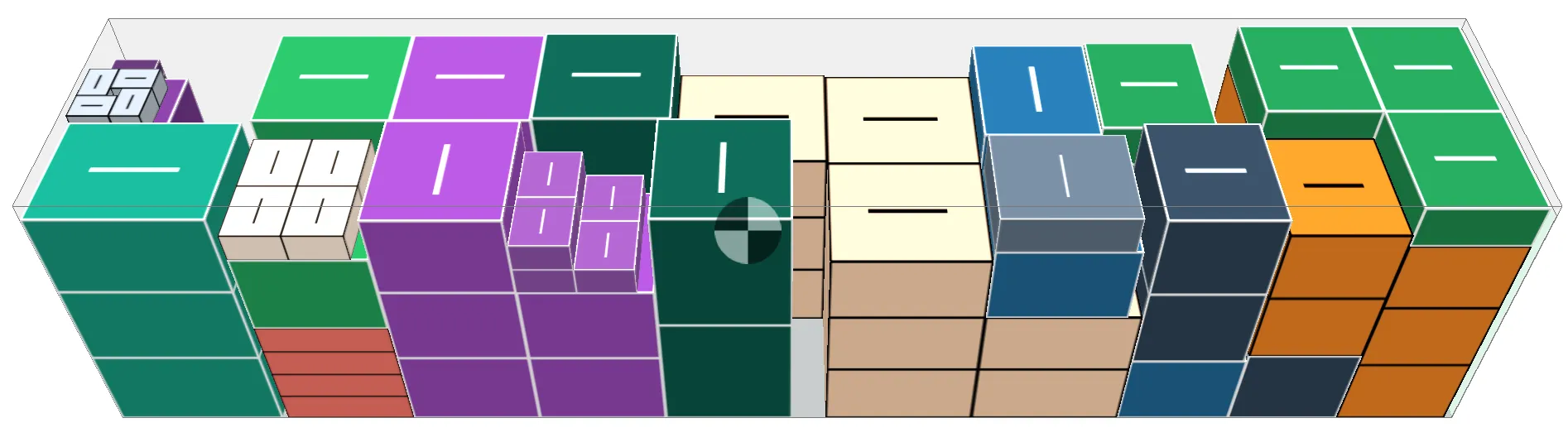

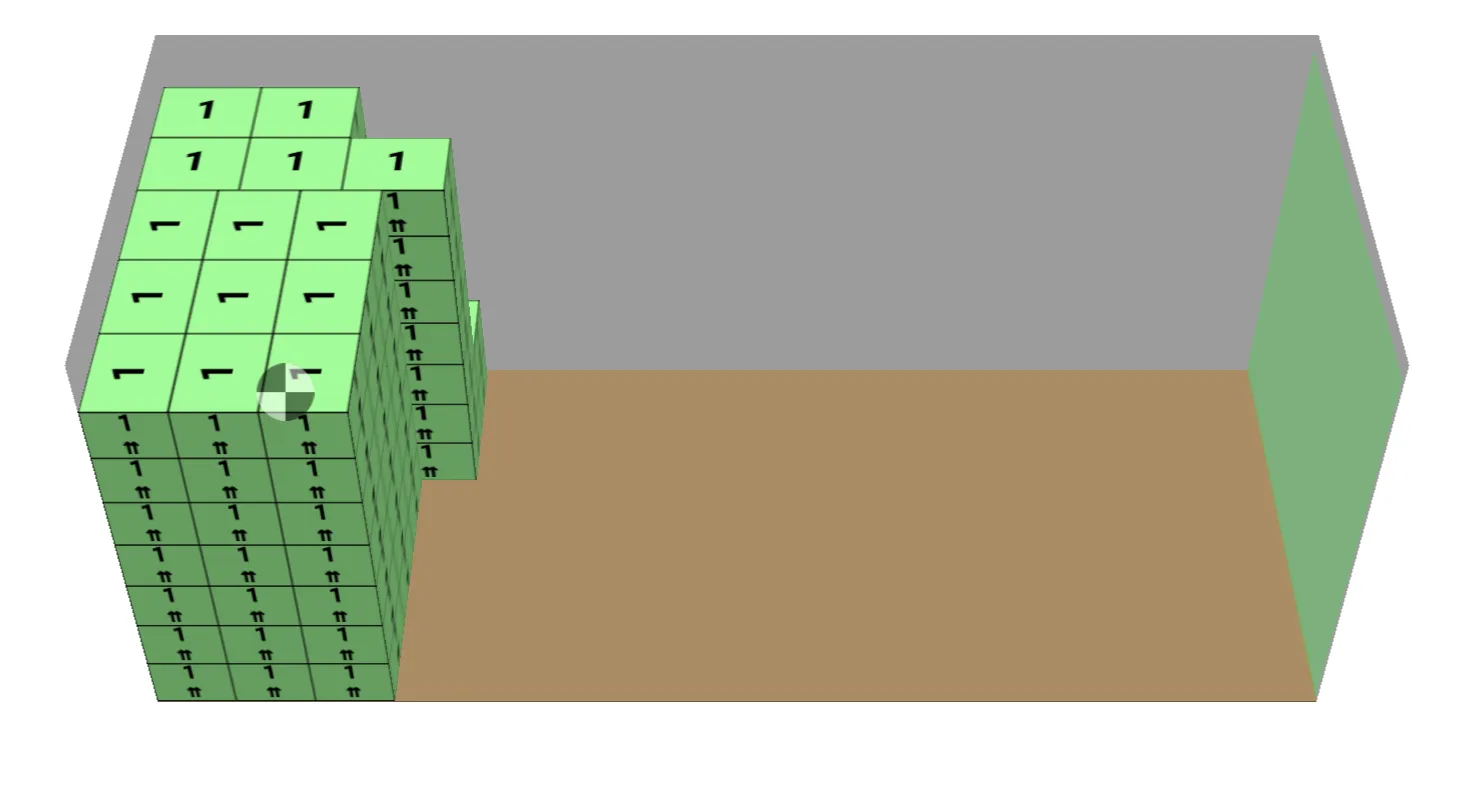

Relating to the example found under Second objective setting, still using “Minimize used height” and “Load from bottom” to true the result will look like:

Prioritize Center of Gravity

This setting will try to place items near the center of gravity. If enabled then the center of gravity will be within 10% from the center of the container.

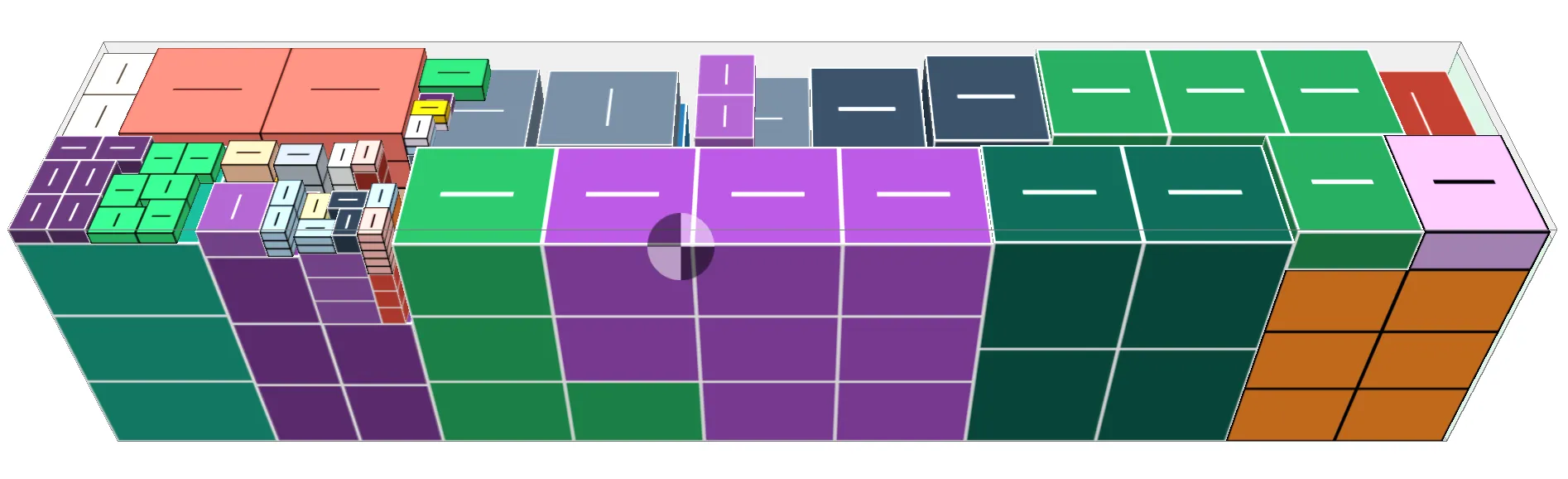

Load containers in sets

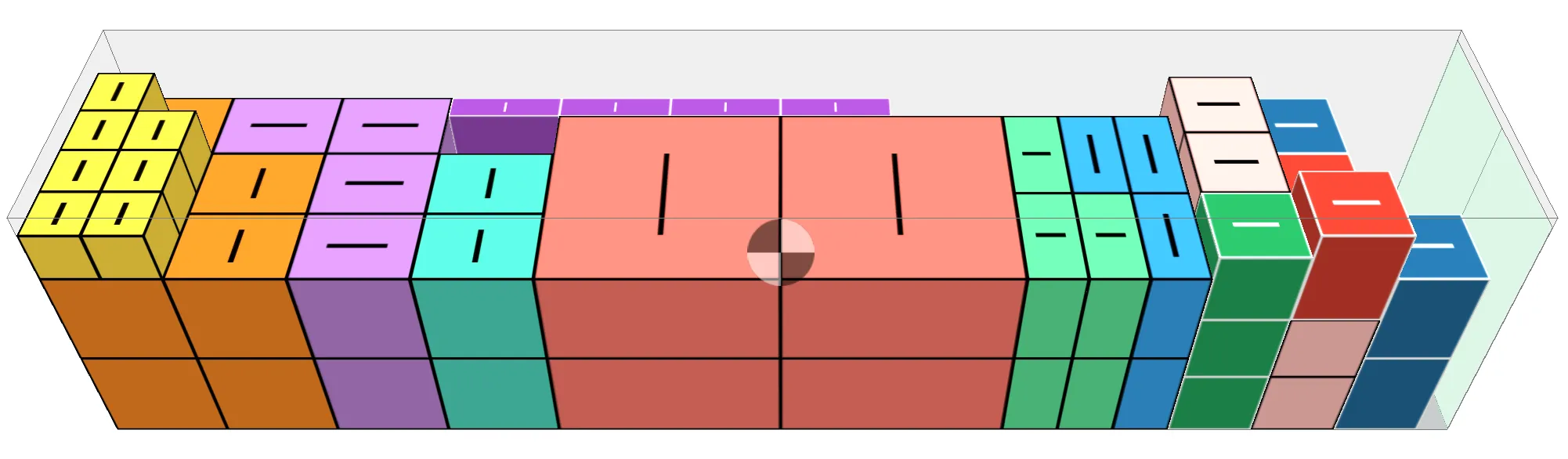

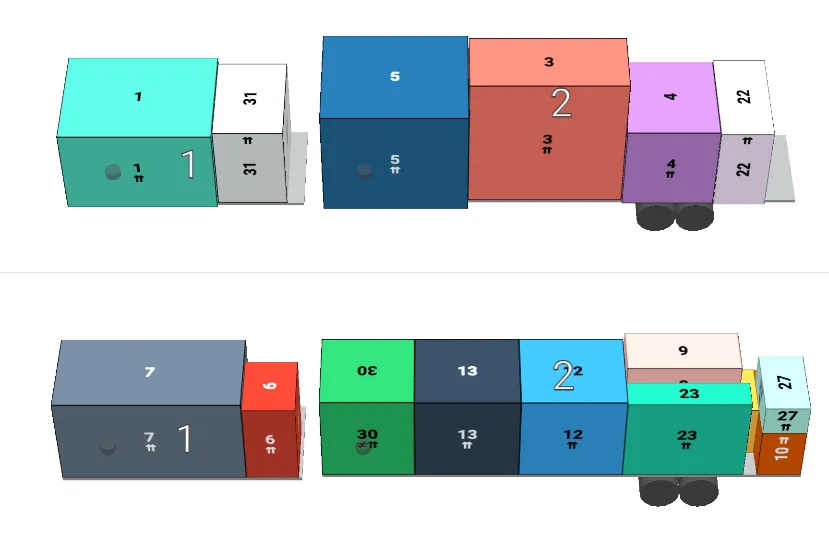

This setting is especially interesting for trucks & trailers. Lets say that you want to load a truck set with a front and rear trailer, like the commonly used Superlink in Africa. Then enable this setting and the selected equipment will alternate like below:

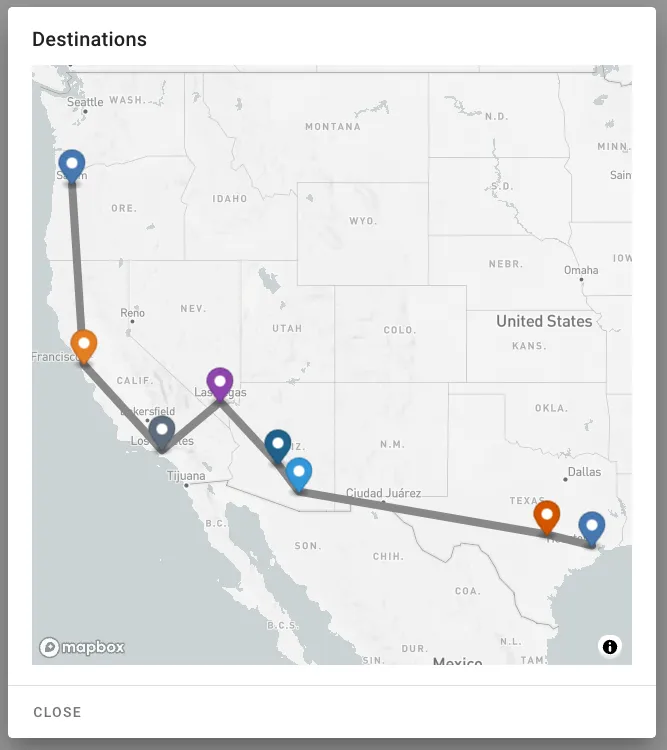

Routing

In loadplans for Road trailers there is a setting called “Enable Routing”. If you have a Port of Loading and the cargoes have the Destination field filled in, Cargo-Planner will create a delivery route and pack the cargoes in order of delivery.

This setting will override any priority set on an item

In order to improve the accessibility of cargoes at each stop it’s recommended to combine this with the Better organization setting.

Cargo

Shipping factor

Shipping factor is used to calculate volumetric weight. The entered factor is applied based on the provided unit (cm3/kg, kg/m3, cu in/lb or lb/cu ft).

Volumetric weight is calculated by multiplying the volume of each cargo by the provided shipping factor.

The volumetric weight is compared against the package’s actual weight. Whichever number is higher is used as the chargeable weight which may affect the loading of cargoes.

Error margin

A value in % (from -50 to 50) that describes how the dimensions of the cargoes should be interpreted.

If set to for example 10 - then a cargo that is 1x1x1 m will be enlarged so that its volume will be 1.1 m³. This might be useful if the cargo dimensions is not totally accurate.

In the same way if a value of -10 is provided then the cargo will be smaller than the provided dimension. This might be useful to simulate cargoes that can be “compressed” when loading by pushing and squeezing.

Allowed overhang

If you allow a cargo to not have full support from below you can change the allowed overhang setting. Setting it to 0 means all cargoes needs full support from below.

Heavier cargoes can be stacked on top of lighter ones

Usually a cargo weighing 100kg cannot be loaded on a cargo weighing 50kg. However a box weighing 5kg can usually be loaded on a box weighing 4 kg. There are different opinions on this so you can change it here to fit your requirements. It will likely affect the utilization.

This setting is set to true by default!

Consignments

These settings only affect cargoes that has has a Group / Consignment ID set.

Entire consignments must be loaded or none

Enable this setting if you want to make sure that all cargoes of the same consigment ID will be loaded. If not all cargoes can be loaded, none will be loaded.

Different consignments cannot be mixed in the same container

By default two different cargoes with different Consignment IDs can be loaded into the same container. This setting will load them in separate containers.

Consignments must be grouped together

Use this setting if you want to make sure the consignments does not get split up into different containers.

Note that if the consignments does not fit any of the selected equipment they will not be loaded and put under “Unloaded items”

Secondary

These settings have the same parameters as the primary settings, but they only apply to preloaded hold types. A good use for this is if you are loading your cargo on pallets and then into a trailer, you might want different behaviour when loading the cargo on a pallet, like loading from the bottom up, than when loading the pallets into the trailer.

Custom Rules

Custom rules is a topic in itself which is covered here

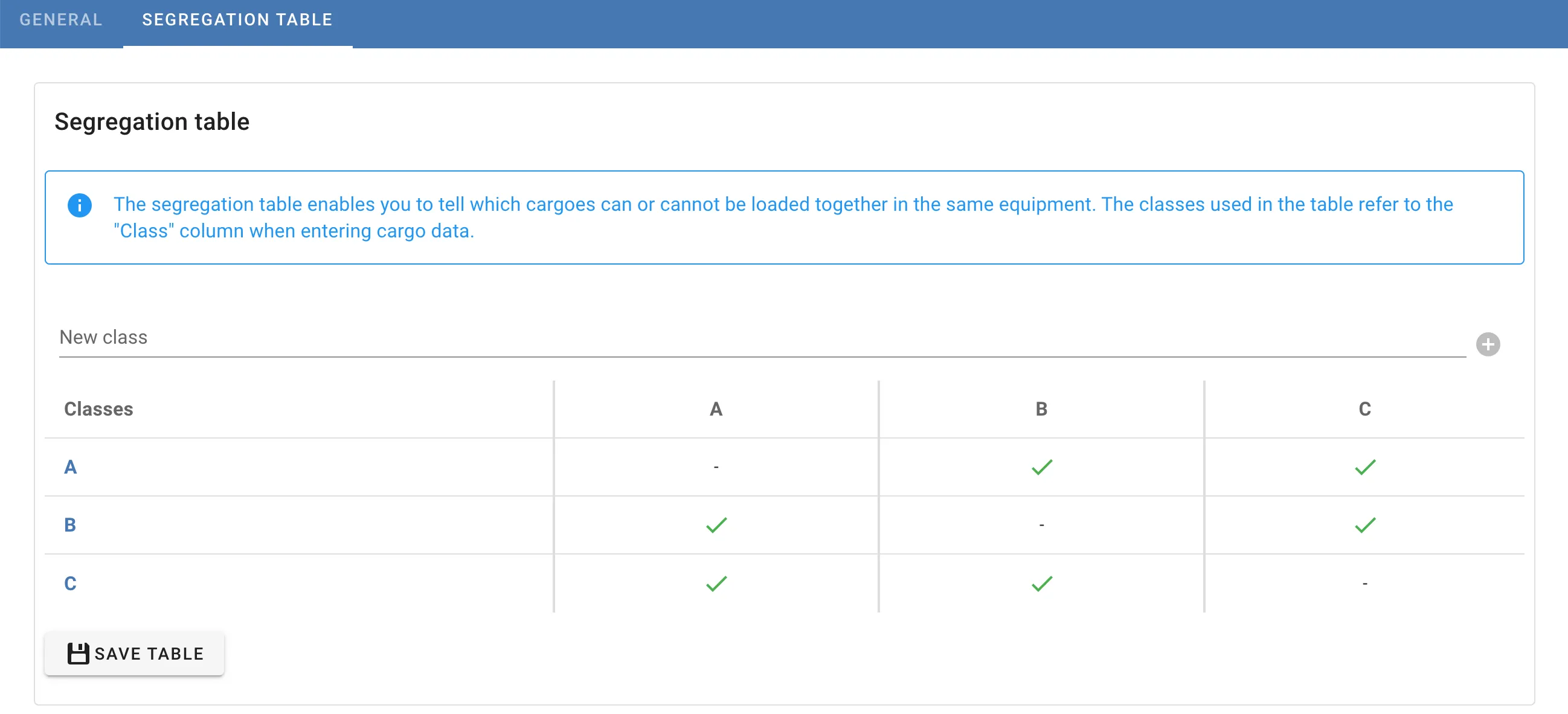

Segregation table

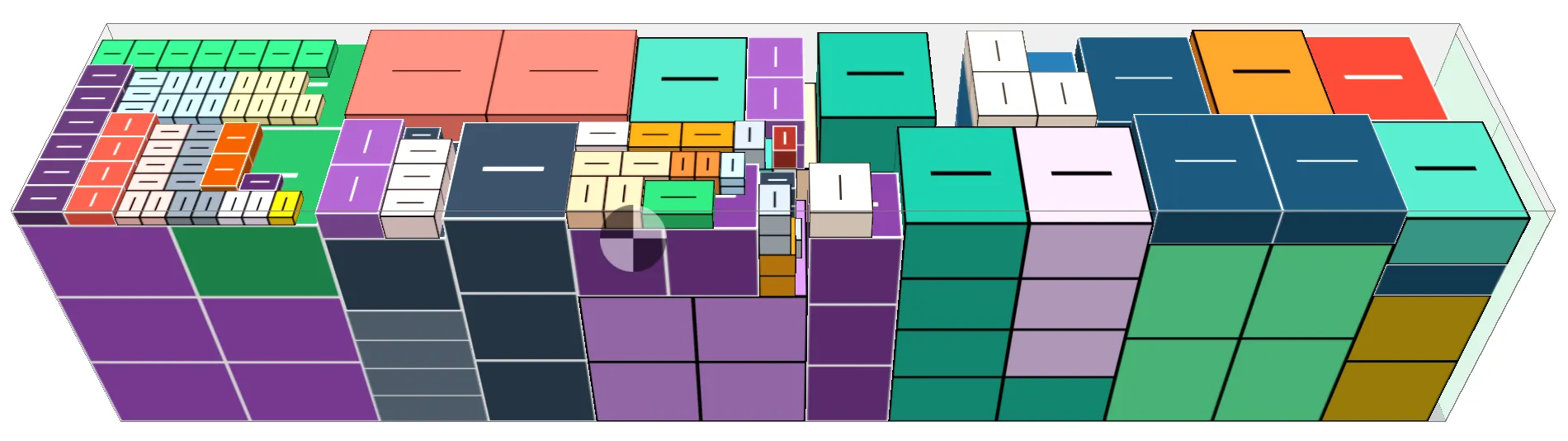

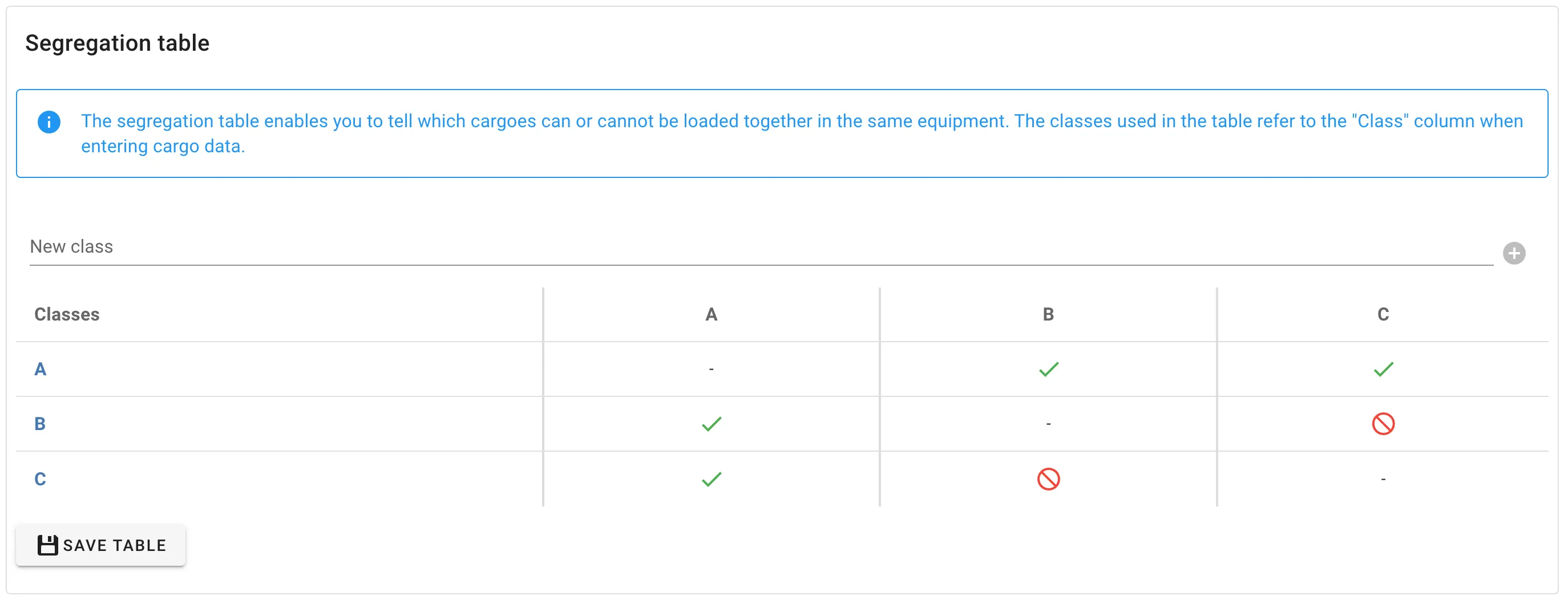

The segregation table enables you to tell which cargoes can or cannot be loaded together in the same equipment. Start by creating classes for your segregation table. To add a new class enter a class name and press the add button.

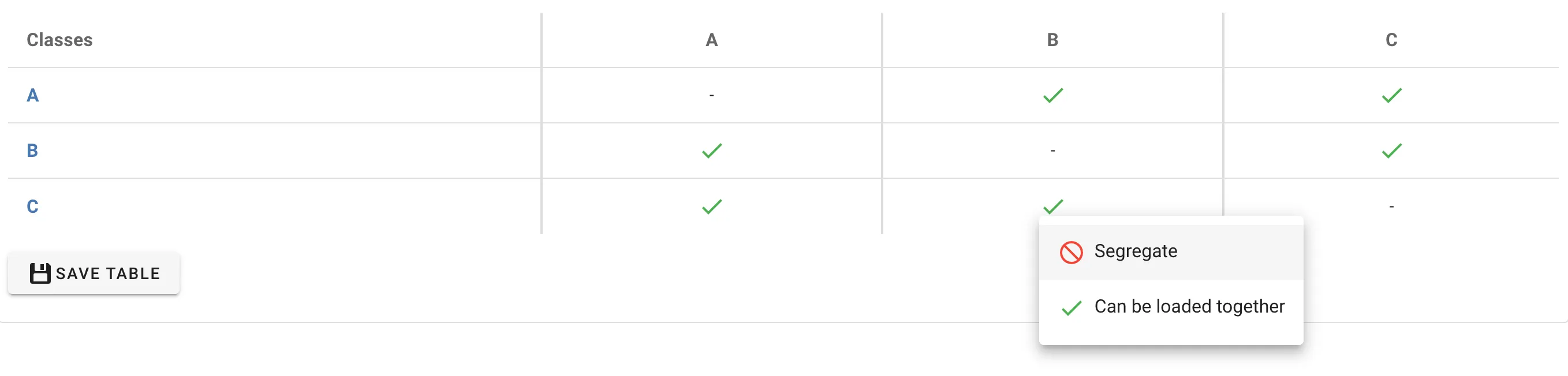

When you have created your classes you need to define which classes that can not be loaded together. If class B cannot be loaded together with class C, press the checkmark in column B on row C and click “Segregate”.

The table will be updated indicating that B and C are segregated on corresponding rows. To remove the restriction, click on the same cell and select “Can be loaded together”.

Note that you have to click SAVE TABLE for changes to take effect.

The classes used in the segregation table refers to the “Class” column when entering cargo data. In our case, thanks to the segregation table, the second item (Class B) will not be loaded in the same container as the third item (Class C).